Building Frames: Wood

Being the essential ingredient in building frames, wood selection is pretty important. Depending on where you get the wood, the selection can go from a few acceptable types to overwhelming.

Grades

Lumber is graded for quality. Hardwoods (deciduous) are graded using one system, and softwood (conifers) are graded on another.

| Grade | Abbreviation | Comment |

|---|---|---|

| First and Seconds | FAS | Best grade, clearest, very few defects |

| Select | SEL | Close to FAS, uses for less wide boards |

| #1 Common | #1 Com | around 66% clear |

| #2 Common | #2 Com | around 50% clear |

| Grade | Abbreviation | Comment |

|---|---|---|

| A Select | C | Clearest, no visible defects |

| B Select | D | Small defects, mostly clear |

| C Select | C | Clearest, very few defects, one side may be very clear |

| D Select | D | Close to C, will have small knots and defects |

| 1 Common | #1 CON | Construction grade, with moderate-sized tight knots |

| 2 Standard | #2 STD | More defects than #1 |

With hardwoods, anything below Select will be problematic for framing. The amount of waste (unusable wood) outweighs any savings in cost. With softwoods, anything below C is pretty much unusable.

Selection

Ideally, you want to buy clear, straight and flat boards. Take your time and carefully examine each piece. The first thing to check is the appearance, looking for knots, defects, grain and color. Then hold the board on edge and sight down it, looking for straightness. Some warping is inevitable, but don't buy a severely warped board. Check for excessive cupping, or bowing from side to side on the board. Check for splits. A kiln-dried board will often have splits on the ends, but these should not extend more than a few inches.

Species

You can make from from most species (pretty much any), but some are more common than others. The main differences comes down to availability, workability, and appearance. If you are building a fair amount of frames, it is worth getting some samples of different woods and actually finishing them, to get a feel for what works for you.

An excellent source of information on wood for wood working is Christian Becksvoort's With the Grain, 2013 Lost Art Press, ISBN 978-0-9850777-4-7.

The samples shown are unfinished on the left, and finished with a clear polyurethane on the right.

Cherry

Cherry is probably the most popular wood for making furniture. It is hard enough to be quite durable, but still works nicely. The coloring runs from pinkish to red brown. As it ages, cherry will darken, gaining in richness of color. Cherry is readily available, and readily inexpensive. It makes for a nice frame if the warmness works with the image.

Maple

Maple is my personal favorite. There are two types of maple, hard and soft. Hard has a much more consistent grain, while soft is more noticeable. I use hard. It has a very nice warm color, which is more cream than yellow. Maple's very tight pores means it finishes very smooth. It works very nicely, in that it cuts clean and crisp. It is, however, quite hard. Keep everthing sharp. Maple is readily available, and fairly inexpensive.

Oak

Oak, both white and red, is readily available and fairly easy to work. White is much more durable than red, and do to the more neutral coloration is perhaps better suited for frames. Oak does, however, have large pores, which means that getting a very smooth finish requires some extra work. This is an aesthetic thing, and may not be of concern.

Poplar

Poplar is normally used as a secondary wood, as its color can vary a lot. Not the prettiest of woods, is is light in weight and quite easy to work. Poplar is also one of the least expensive woods. It will do fine if frames are going to be painted.

Pine

Pine, or more specifically Eastern white pine, is another relatively inexpensive choice that works quite well. It looks fine with a natural (clear) finish, or can be painted. Most big-box home centers sell a version that is S4S (sanded four sides). The 1 × 2 version measures 1½ by ¾ inches, and can be used as is, without having to rip or plane.

Walnut

When a naturally dark frame ias required, walnut would be the obvious choice. It is very workable. It is also on the expensive side. Caution should be used when working walnut with power tools, particularly sanders, as the dust can be an irritant.

Reclaimed

Reclaimed, found, or recycled wood can be fine. It may take a lot of work to get it into shape, which should be taken into consideration. The biggest problem is removing any metal, which must be done very carefully.

Measurements

It gets pretty confusing sometimes, but wood is sold several different ways. Big-box home centers will sell it by the piece (like premium pine 1×2), or by the lineal foot or length.

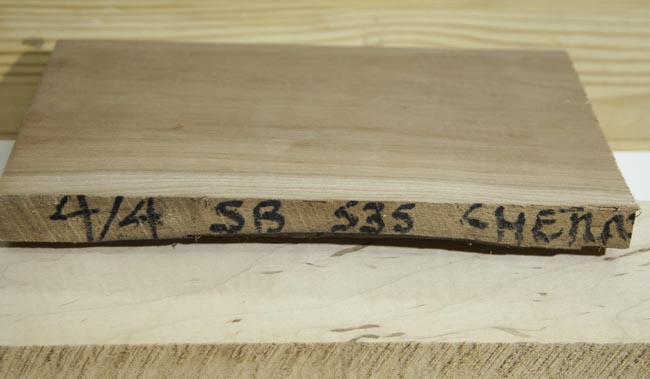

Lumber yards will typically sell S3S boards of varying lengths and widths, but standard thicknesses. The thickness is measured in quarters of an inch, before drying. So a 4/4, or four quarter, piece will be something over 3/4 inches thick. Boards are usually priced and sold by the board foot, which is calculated as width in inches times length in foot times thickness in inches divided by 12. Or use a board foot calculator, which are easy to find.

When buying/acquiring wood, be sure to get extra. Most recommend about 20% more than you need, allowing for wastage and mistakes. It is a good idea to let it sit in your workspace for a few days, or even a few weeks, to let the wood acclimate.